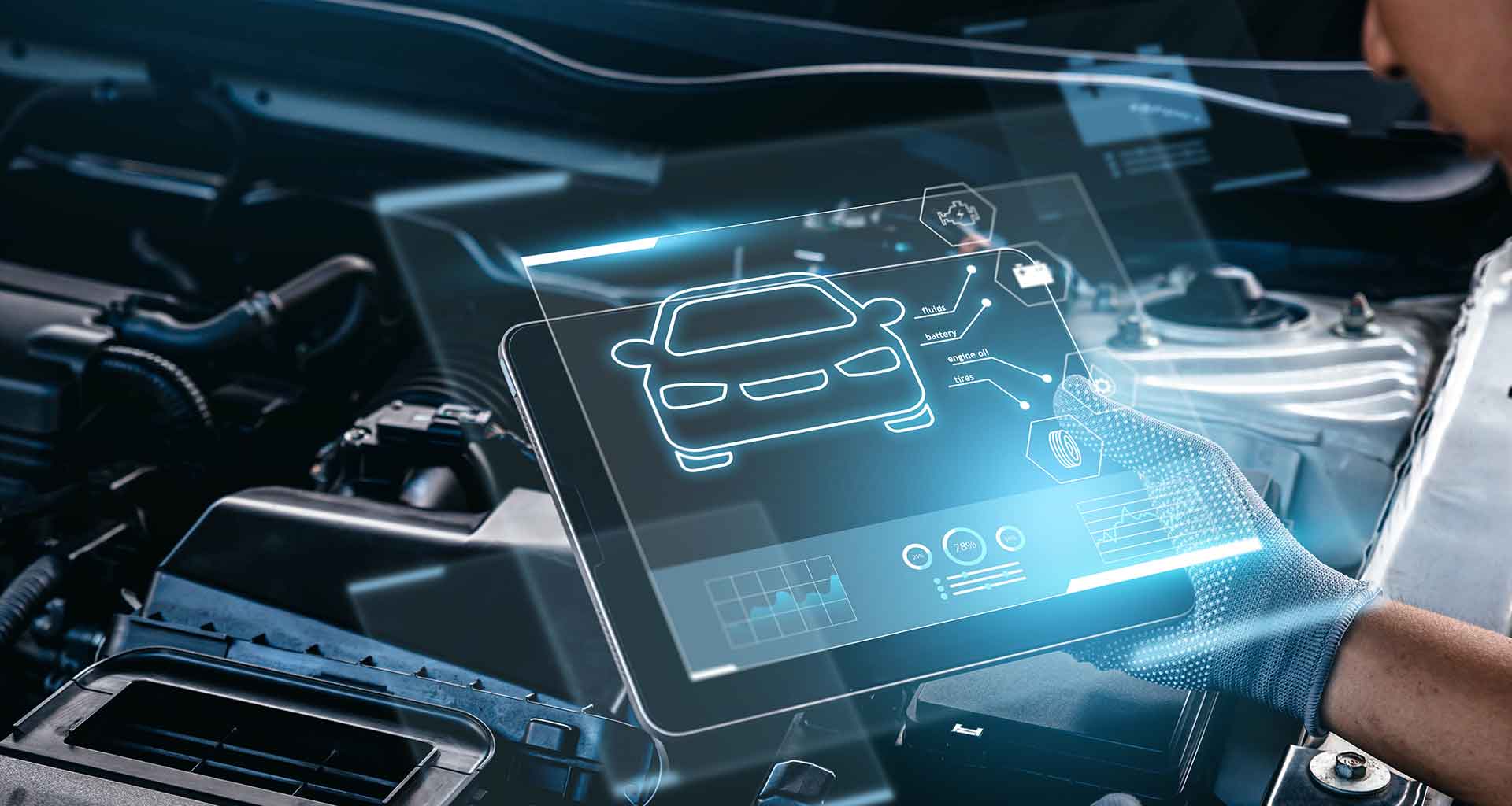

The number of Electronic Control Units (ECUs) in a car can vary between 20-100+ depending on the vehicle class, level of electrification, and feature set.

Low specification vehicles typically have around 20-30 ECUs for basic powertrain, chassis, and body-electronic control.

Mid-range models more often integrate 30-70 ECUs to support increased connectivity, comfort, and safety systems.

Higher-end or fully featured vehicles (with extensive driver assistance, infotainment, multiple zones of climate and connectivity) commonly include 70-100+ ECUs.

Global vehicle production surpassed 90 million units in 2023, with 85% integrating multiple ECUs per vehicle. Infotainment and telematics ECUs were in strong demand, with 58% of new passenger cars worldwide featuring connected infotainment systems.

ADAS is another trend driving ECU installations, with 42% of new cars globally incorporating features like lane assist, adaptive cruise control, and emergency braking. This has increased demand for radar, LiDAR, and camera-based ECUs.

Electric and hybrid vehicles are reshaping the automotive ECU market. EVs require between 80-100 ECUs, nearly double the number found in combustion vehicles. Battery management ECUs alone represent 15% of ECU demand in EVs, ensuring efficient energy utilisation. In 2023, global EV sales exceeded 14 million units, significantly boosting ECU demand.

China sold over 8 million EVs, while Europe contributed 3.2 million units. With more than 30% of EV buyers demanding advanced connectivity features, ECU integration for infotainment, telematics, and ADAS is increasing rapidly. This surge in EV adoption positions electric mobility as the strongest driver of ECU demand.

The move away from ECUs

However, recent industry shifts to software-defined vehicles are driving a move away from hundreds of ECUs towards centralised computing platforms, where multiple functions run on high-performance processors.

Tesla currently holds a significant lead in this zonal architecture design. Instead of applying dozens of function-specific ECUs scattered throughout the vehicle, Tesla has consolidated control into a number of high-performance computers, organised around zones and centralised compute.

Each are responsible for broad functional domains:

- Vehicle Control Unit (VCU) handling body, chassis, and powertrain coordination

- Infotainment and user interface computer managing displays, connectivity, and user interaction

- Autopilot/Full Self-Driving (FSD) computer processing camera, radar, and sensor data for ADAS and automated driving functions

In more recent vehicles, Tesla further aligned these systems with a zonal philosophy, where physical zones of the vehicle (front, rear, left, right) aggregate sensor and actuator connections locally, while intelligence remained centralised.

As a result of this architecture, Tesla vehicles typically use fewer than 20 major control units, depending on model and generation.

The zonal architecture essentially means the vehicle can be treated as a software-defined system and functions that are traditionally locked to hardware ECUs become software applications running on shared compute.

Virtual ECUs (vECUs)

vECUs are software functionalities that can be executed without physical hardware, facilitating cost-effective testing within simulated environments

In September 2022, Renesas Electronics launched an integrated development environment for automotive ECUs containing multiple hardware devices. The platform supports co-simulation, debugging & tracing, high-speed simulation & distributed processing software over multiple SoCs and MCUs without hardware. This software development environment recognises the automotive industry’s shift toward ‘Software First’ product development, in which a vehicle’s value is increasingly defined by its software, as well as the ‘Shift Left’ software design approach, which emphasises software verification and validation earlier in the development cycle, before hardware is available.

According to market research, vECUs help developers identify integration issues early and provide a stable, scalable environment for software validation. Furthermore, collaborations between technology firms have led to virtual platforms that support Cloud-native application development, allowing automakers and Tier-1 suppliers to build and test next-generation mobility solutions more flexibly.

Developing a vehicle with virtual ECUs is like using a high-fidelity flight simulator to train pilots and test aircraft systems before the physical plane has even been built, allowing for safe, rapid, and repeatable adjustments in a risk-free digital environment.

Conclusion

In summary, the number of ECUs in a vehicle is no longer defined solely by quantity but increasingly by function, capability, and software integration. Traditional vehicles typically carried 20–100+ ECUs, with numbers rising in higher-end and electrified vehicles due to advanced infotainment, ADAS, and battery management requirements.

However, the industry is shifting toward centralised and zonal architectures, as exemplified by Tesla. This approach consolidates multiple vehicle functions into fewer, high-performance computers, often reducing major physical ECUs to fewer than 20 per vehicle while enabling a software-defined system. In parallel, virtual ECUs allow developers to test and validate functionality in simulated environments without physical hardware, supporting earlier software integration and faster development cycles.

Overall, while the unit count of physical ECUs per car may decline, the complexity, value, and strategic importance of each ECU is increasing. The market is therefore transitioning from a high-volume, hardware-centric model to a fewer-but-more-capable ECU paradigm, driven by electrification, advanced driver assistance, connectivity, and software-defined vehicle strategies.