Selecting the right sensor is a critical step in electronic system design, influencing accuracy, reliability, and long-term performance.

As products become more connected and application-specific, engineers must consider more than basic specifications – factors such as operating environment, power consumption, integration constraints, and supply continuity now play a central role. With a wide range of sensing technologies available, understanding their strengths and limitations helps designers make informed choices that reduce risk and streamline development across modern electronic applications.

The expanding role of sensors in modern design

Sensors are the foundation of every intelligent system. They convert physical phenomena – such as temperature, proximity, or magnetic field strength – into actionable electrical signals. Their ubiquity across industries underscores their importance:

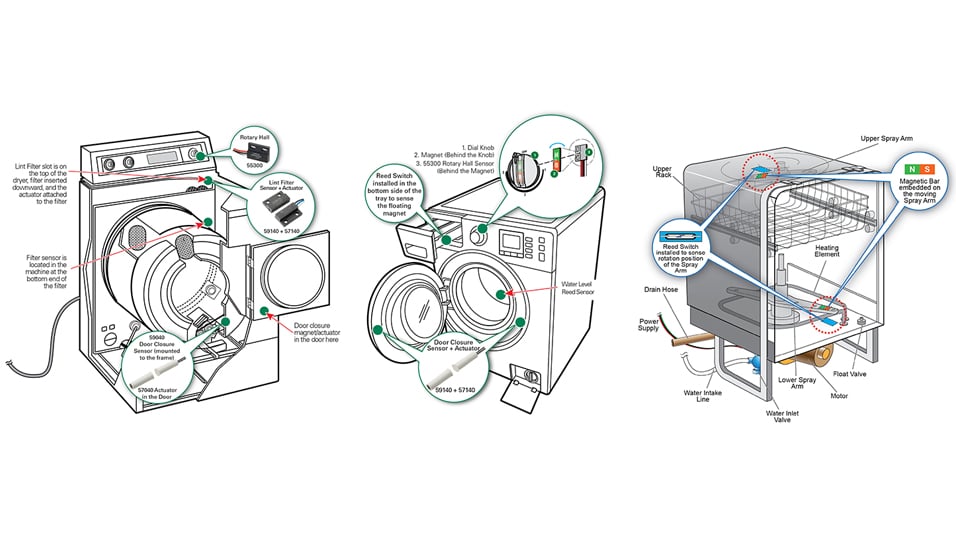

• Appliances: provide temperature regulation, motion detection, fluid levels, and user safety

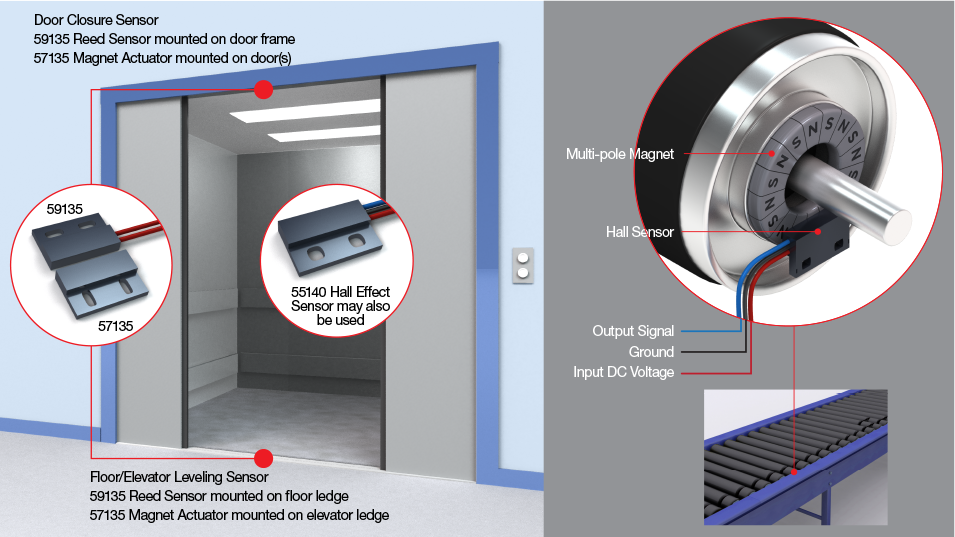

• Building/industrial automation: enable adaptive lighting, efficient HVAC control, and security

• Automotive/electric vehicles (EVs): essential for safety, energy management, and user experience

• Factory automation/robotics: guide machinery, maintain process accuracy, and ensure worker safety

As designs become more compact, energy-efficient, and interconnected, engineers must select sensors that deliver precise performance within tighter design constraints.

Six core sensor types in electronics design

While sensors span a wide range of technologies, six categories dominate electronics applications. Understanding their strengths helps engineers choose the right one for their design priorities – whether that’s low power, precision, isolation, or size.

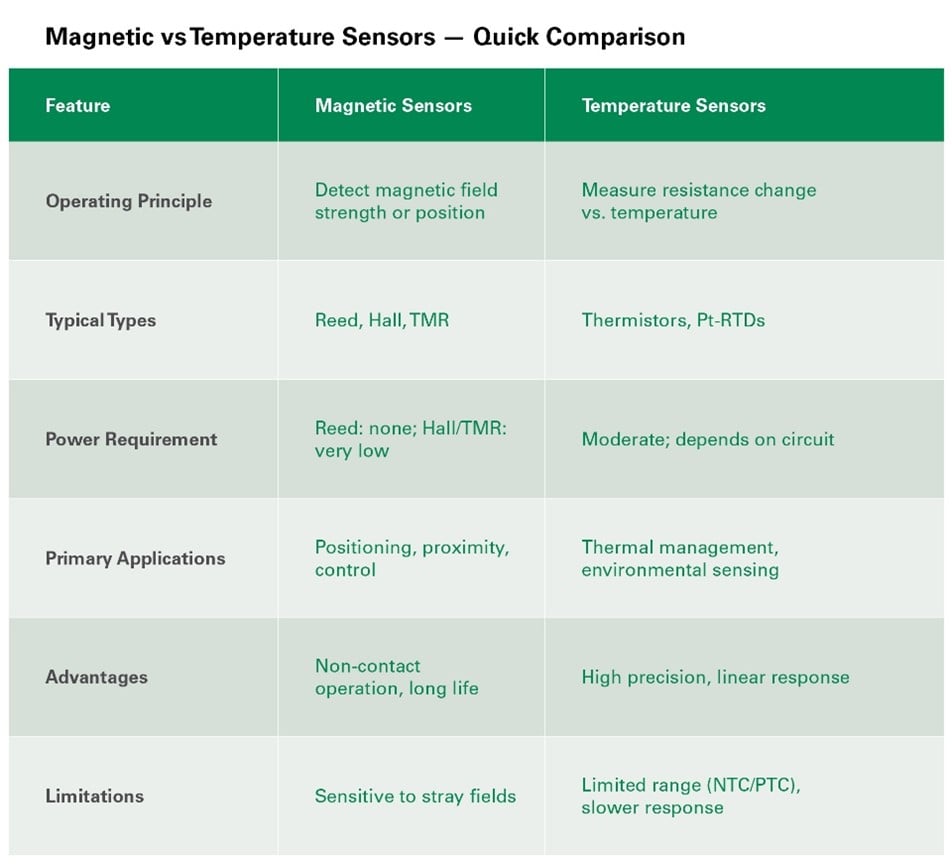

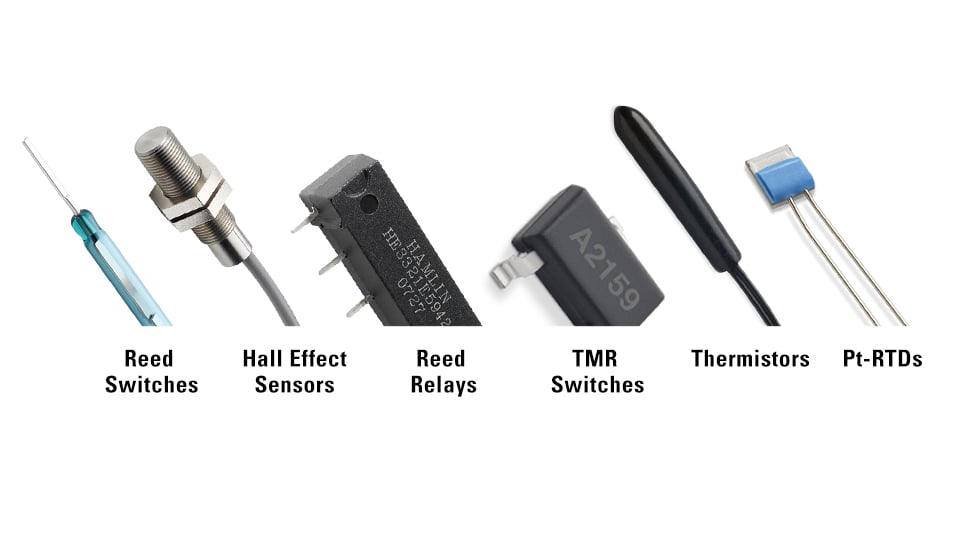

1. Reed switches

Reed switches contain two ferromagnetic blades sealed in a nitrogen-filled glass capsule to prevent corrosion. When a magnetic field is applied, the blades attract and close, completing the circuit. These switches operate without external power, offering exceptional reliability and efficiency for battery-powered or safety-critical designs.

2. Hall Effect sensors

Based on semiconductor physics, Hall Effect sensors output a voltage proportional to the strength of a magnetic field. They require signal conditioning and temperature compensation but provide continuous detection for applications such as rotary encoders, linear positioning, and non-contact sensing. Their solid-state nature ensures durability and long operational life.

3. Reed relays

Reed relays integrate a reed switch with a coil, providing galvanic isolation between control and load circuits. Their compact form factor, low contact resistance, and high insulation resistance make them ideal for test and measurement systems, medical instruments, and industrial controls that require precise switching with minimal power. (See also Reed sensors.)

4. Tunneling Magnetoresistance (TMR) switches

Combining magnetic tunneling technology with CMOS integration, TMR switches deliver ultra-low power consumption and high magnetic sensitivity. They integrate on-chip voltage generation, signal amplification, and temperature compensation with the TMR sensor to maintain accuracy across wide operating ranges. This makes them particularly attractive for IoT devices, smart meters, and compact electronics. View the Ultra-Low-Power Omnipolar TMR Switches video. (See also TMR sensors, TMR angle sensors, and TMR Magnetic ICs.)

5. Thermistors

Thermistors change resistance with temperature – decreasing for NTC (negative temperature coefficient) types and increasing for PTC (positive coefficient) types. They provide high sensitivity and excellent accuracy over limited ranges, making them suitable for precise temperature control in appliances, battery packs, and environmental sensing.

6. Platinum Resistance Temperature Detectors (Pt-RTDs)

Pt-RTDs offer near-linear resistance change over a broad range (−70 to 500°C for a thin-film Pt-RTD), making them ideal for industrial systems requiring stable and repeatable temperature monitoring. Their reliability and long-term drift resistance make them a go-to for critical process and instrumentation applications.

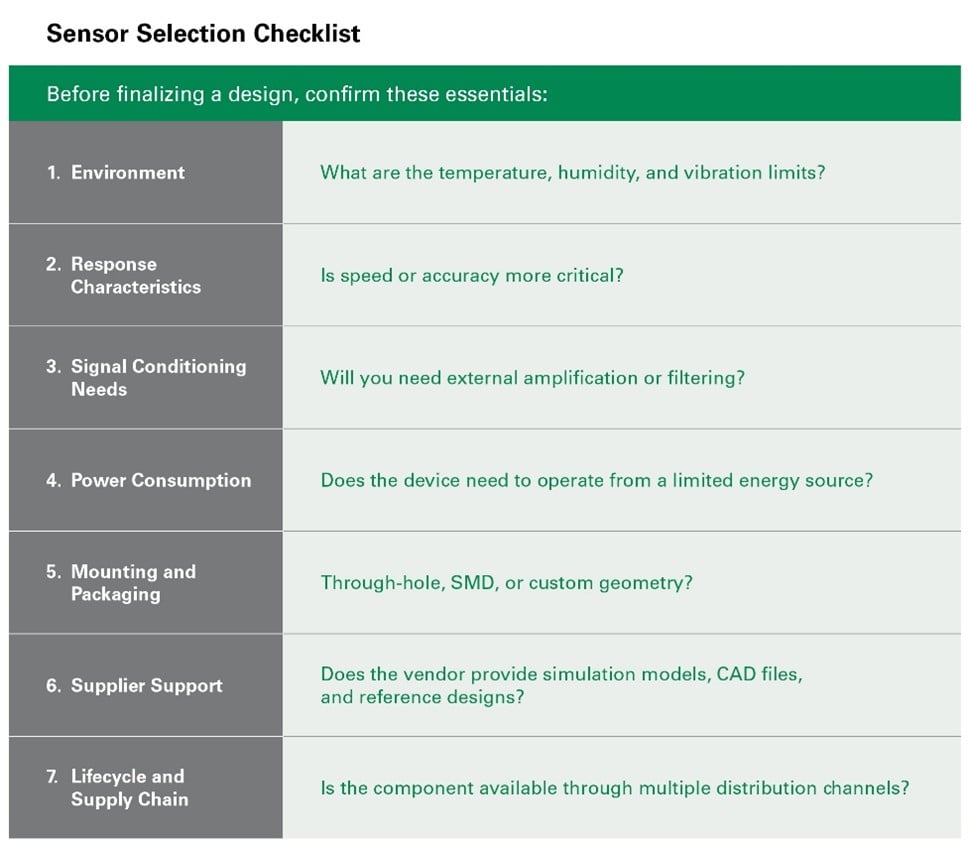

Four key questions to guide sensor selection

Selecting the correct sensing technology is just one part of the design equation. Choosing the right supplier can significantly influence engineering efficiency, customisation options, and long-term supply assurance.

1. Does the supplier offer a broad sensor portfolio?

Suppliers with expertise across multiple sensing technologies can support consistent design approaches and simplify qualification across related applications. A broad portfolio also suggests deeper application knowledge and longer-term product continuity.

2. What level of application support is available?

Access to experienced application engineers can help identify environmental and integration challenges early in the design process. This support is particularly valuable when accounting for factors such as temperature variation, EMI, vibration, and packaging constraints.

3. Are custom-engineered solutions available?

When standard sensors do not meet dimensional, sensitivity, or interface requirements, suppliers with customisation capabilities can adapt existing designs to better fit the application. Simulation tools and mechanical modelling can support these modifications without disrupting manufacturability.

4. Can the supplier support production scale and continuity?

Reliable production capacity and global manufacturing support are essential as designs transition from development to volume production. Suppliers with scalable output and established logistics help ensure consistent availability over the product lifecycle.

Design efficiency starts with the right supplier

A sensor that perfectly fits your specifications but comes from an unreliable or limited supplier can create downstream risks. Conversely, a slightly higher initial cost from a well-supported, high-capacity supplier may yield significant long-term savings in development time, warranty claims, and customer satisfaction.

Today’s leading component manufacturers combine global production capabilities with advanced design support. Many modern facilities use automated testing and calibration to ensure consistent quality across product lines. Engineers who prioritise these attributes during supplier selection often find that their total cost of ownership decreases – even if individual sensor prices are higher.

Designing for performance, reliability, and scalability

Effective sensor selection requires balancing technical performance with practical design considerations such as environment, lifecycle expectations, and manufacturability. No single sensing technology suits every application, making early evaluation of trade-offs essential to avoiding redesigns and delays. Just as important is choosing suppliers that can support customisation, scale, and long-term availability. By combining application knowledge with thoughtful supplier evaluation, engineers can design reliable systems that perform consistently from prototype through production.

For more in-depth information, download ‘Eight Considerations When Purchasing Sensors’ and the ‘Sensing Products Selection Guide’, courtesy of Littelfuse, Inc.

About the author:

Barry Brents is a Field Application Engineer at Littelfuse. He is a former US Navy nuclear submarine officer and a licensed professional electrical engineer in Colorado and California. He has been with Littelfuse for 35 years (including acquisitions), and his current responsibilities include technical support, design assistance, and training for customers and salespeople. Barry received his B.S.E.E. from Texas Tech University.