President Donald Trump has announced a 10% tariff on imports from eight European countries, starting 1st February 2026. The targeted countries are Denmark, Norway, Sweden, France, Germany, Finland, the Netherland, and the UK.

The tariff will target all goods from these nations entering the US market.

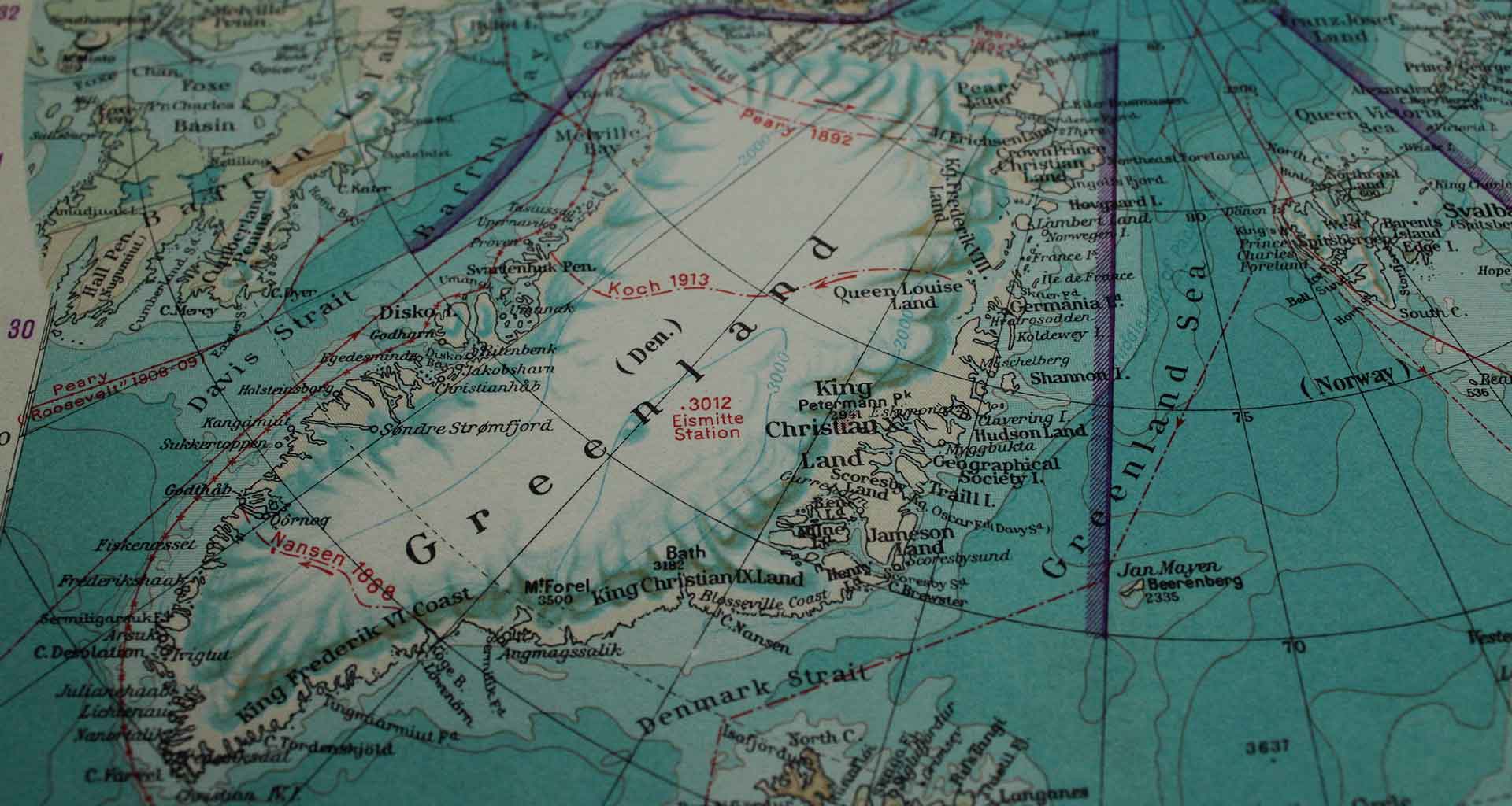

This new tariff is linked to Trump’s demand that Denmark sell Greenland to the US, which is an idea that Denmark and Greenland have rejected.

If no deal is reached over Greenland, Trump said the tariff will rise to 25% on 1st June 2026 and stay in place until the US secures what he calls “the complete and total purchase” of Greenland.

Why is this situation so unusual?

Traditionally, US tariffs are set for economic reasons, such as protecting domestic industries, responding to unfair trade practices, or addressing larger trade deficits. They are not normally used to force sovereign nations to cede territory, as in this case.

European leaders have strongly condemned the tariff threat, calling it “economic coercion” and warning that it could start a trade war. Retaliatory measures are now being considered, which include invoking trade defence mechanisms designed to counter coercion.

The UK’s response

Prime Minister Keir Starmer has urged calm diplomacy and condemned the use of tariffs against allies, warning that such measures could damage vital strategic relationships.

Dr Jonathan Owens, Senior Lecturer in Operations Management at the University of Salford, has said: “If enforced, [these] tariffs could have a significant ripple effect across UK supply chains, particularly for manufacturers, exporters, and logistics providers with strong transatlantic links.

“The US is one of the UK’s largest trading partners, accounting for billions of pounds in exports each year across sectors such as automotive, aerospace, pharmaceuticals, food and drink, and advanced manufacturing. A blanket 10% tariff would increase costs for US importers of UK goods, potentially reducing demand and placing pressure on UK producers to absorb price increases or renegotiate contracts.

“Supply chains could also face indirect disruption. Many UK manufacturers rely on complex, multi-country supply networks that include US components, raw materials, or distribution hubs. Higher tariffs may lead to delays at ports, increased administrative burdens and a re-evaluation of sourcing strategies, all of which could raise operational costs and extend lead times.

“Small and medium-sized enterprises (SMEs) are likely to be disproportionately affected, as they often lack the financial flexibility to offset tariff impacts or rapidly diversify markets. Logistics providers may also experience fluctuating volumes and increased compliance requirements, further straining capacity.”

Industry bodies are calling on the UK government to engage proactively with US counterparts to secure exemptions or mitigating measures, while urging businesses to reassess the resilience of their supply chains. In the months ahead, scenario planning, supplier diversification, and closer collaboration with logistics partners will be essential.

Compounding geopolitical tensions

These developments come at a time when the electronic components market is only just emerging from a prolonged period of geopolitical disruption, including US-China trade tensions, export controls on advanced semiconductors, the war in Ukraine, and instability in key shipping routes such as the Red Sea. For procurement professionals, this has already meant extended lead times, constrained supply, price volatility, and increased compliance requirements.

Against this backdrop, the prospect of new transatlantic tariffs risks reintroducing uncertainty just as supply chains were beginning to stabilise.

While the tariffs remain unconfirmed, the prospect of their introduction underscores the importance of trade stability and reinforces the need for UK businesses to prepare for further global trade disruption against a backdrop of fragile UK growth.

Want to learn how to future-proof your supply chain in 2026? Join our upcoming webinar to hear from industry experts.