Counterfeits come in many guises. The most basic definition of a counterfeit is “an imitation intended to be passed off fraudulently or deceptively as genuine, for profit.”

In times of supply shortage, or where component obsolescence limits availability, the prevalence of counterfeit devices often multiplies.

As awareness increases, so does sophistication.

We have moved far beyond incorrect manufacturers logos and IC packages with no die inside caught by the simplistic visual inspection testing used by those following AS6081. The counterfeiters now have very sophisticated operations as the potential gains can be enormous.

Customers whose normal supply routes prove insufficient may assume unauthorised or grey market sources are the only solution; and that ‘testing’ can eliminate quality risks. Nothing could be further from the truth; but there ARE zero-risk sourcing options available.

What is a counterfeit semiconductor?

In the semiconductor world counterfeits include:

- Non-functional or scrap product which is re-marked as good and re-sold

- Functional yet sub-standard product purchased by the counterfeiter remarked and re-sold as full grade product at an increased price

- Recycled and recovered components re-sold as new

- The consequences of allowing sub-standard product to enter the supply chain may include:

- Reduced production yields and increased rework

- Increased in-service failures and reduced reliability

- Heightened risks and financial liability associated with catastrophic system failure

- Cost of reputational damage

What does ‘100% tested’ REALLY mean?

Customers may incorrectly assume ‘testing’ provides a 100% genuine guarantee. At its most basic, 3rd party testing comprises of paperwork and visual inspection, x-ray inspection, basic continuity or functional testing or full functional testing.

Is functional testing carried out over the full temperature range?

When functionally testing a device, FAULT COVERAGE is critical. Without 100% test fault coverage, the device WILL have residual failures. Residual failures are devices that contain faults, but which PASS the testing used.

If the stuck-at condition above is not tested, then fault coverage is 98.96%. Is this acceptable in your critical application?

Effective test requires high fault coverage and accurate fault modelling. AS6171 calls out far greater testing for parts bought through independent distribution and yet is rarely followed.

The only way to offer a 100% guarantee that a device operates to its specification, is to test it using the original component manufacturer’s (OCM) test processes.

Third-party test houses cannot hope to replicate these complex test processes, often only partial electrical and/or functional testing is carried out.

The ultimate tool in the fight against counterfeit is AUTHORISATION.

Authorised after-market suppliers and manufacturers (as called out in the US-DoD DFARS), such as Rochester Electronics, provide the only 100% guaranteed and counterfeit-free source for active-shortage and obsolete semiconductors.

Finished devices stored and supplied by authorised sources are guaranteed to come only from the OCM and to have been stored in-line with the OCM’s recommendations. These products offer a 100% conformance guarantee.

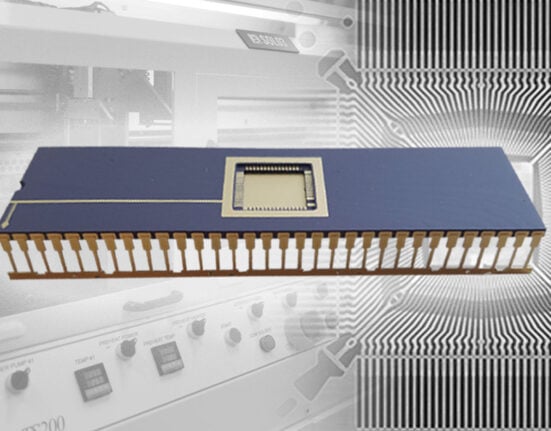

As a licensed manufacturer, Rochester Electronics is also able to offer ongoing production of obsolete devices. Built from known-good-die, these products are tested using the OCM test procedures and, in many cases, the original test equipment – guaranteed 100% compliant to the original specification.

Rochester Electronics is authorised by the OCM to mark its products with the original part number and the current date-code. Many of these devices are still in production 20 years after the original discontinuation.

This article originally appeared in the Jan/Feb issue of Procurement Pro.