When maintaining legacy systems, customers often ask: “Can you rebuild this?”

At Rochester Electronics, the answer is almost always “Yes.” Our proven processes and deep technical expertise enable us to support long-lifecycle programmes and ensure component continuity.

Rochester continuously invests in strategies that sustain legacy systems by managing the components, materials, and tooling used in original product designs. Our approach integrates lifecycle management, tooling preservation, controlled storage, and clear customer communication to minimise risk and maintain part viability.

Even a well-planned Last-Time-Buy (LTB) can fail if parts are stored incorrectly or if essential tooling is lost. Effective obsolescence management must therefore include both material storage and tooling continuity.

The silent risk: vanishing tooling

Tooling is often owned by the customer but managed by the supplier. When a package hasn’t been ordered for 24-36 months, suppliers may scrap or repurpose tooling without notice, leading to costly rebuilds, production delays, and potential programme disruption.

Rochester’s cross-functional lifecycle management process – spanning procurement, engineering, and operations – tracks component history, reviews PCNs and EOL notices, and identifies parts without second sources. When tools remain inactive, maintenance orders are placed to preserve their viability.

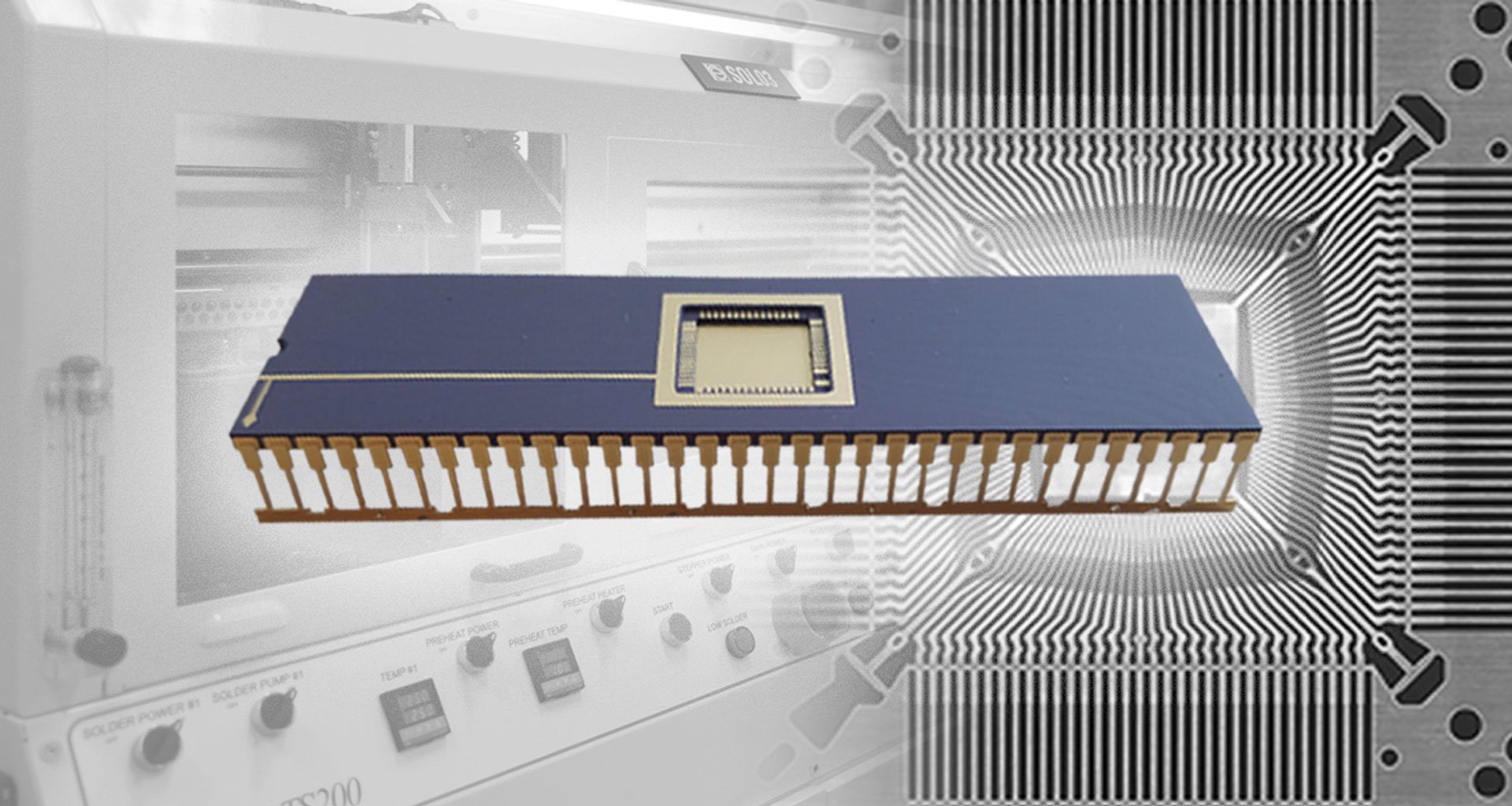

For legacy semiconductor packages such as CERDIP, PDIP, QFP, CQFP, CPGA, and custom ceramic hybrids, specialised tooling is critical. Hermetic packages, in particular, depend on costly tooling that is often scrapped during production lulls, creating major risk for long-term programmes.

Maintaining tooling viability

To sustain manufacturability, Rochester:

- Places low-volume maintenance orders to keep tools active

- Establishes storage and retention agreements with suppliers

- Maintains a tooling registry linked to part numbers

This structured approach safeguards production readiness and prevents costly tooling obsolescence.

Storage as risk management

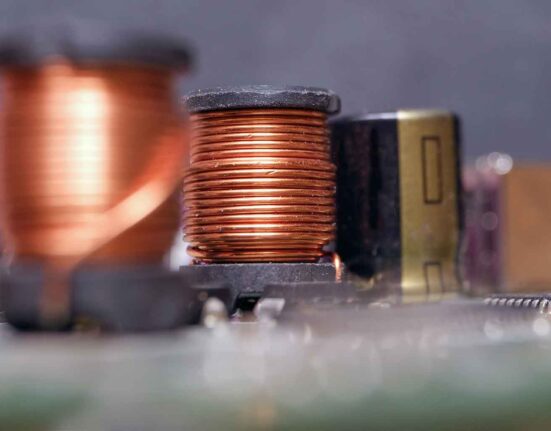

Strategic storage is essential to protect long-term supply. Rochester maintains components under controlled environments to ensure reliability:

- Nitrogen or dry cabinet storage for moisture-sensitive and gold-brazed packages

- FIFO inventory rotation, shelf-life monitoring, and reinspection of aged stock

Proper storage prevents degradation of valuable materials, such as gold preforms, hermetic lids, and specialty passives, protecting performance in critical applications.

Customer collaboration: shared foresight

In aerospace, defence, and other high-reliability sectors, success depends on shared foresight. Rochester partners with customers to forecast demand and mitigate obsolescence by:

- Communicating risks through PCNs and customer reviews

- Offering vaulted inventory and alternate storage solutions

- Aligning Last-Time-Buy planning with tooling and lead-time realities

The key takeaway: foresight ensures continuity

Simply ‘having the part’ is not enough. Sustaining legacy systems requires the tooling, testing, storage, and discipline to keep components viable long-term.

Through proactive storage, tooling retention, and transparent communication, Rochester Electronics extends component availability, programme life, and customer trust.

As a licensed semiconductor manufacturer, Rochester has produced over 20,000 device types and holds more than 12 billion die, enabling the manufacture of over 70,000 device types in partnership with 70+ leading semiconductor manufacturers for more than 40 years.

For more information visit – www.rocelec.com

This article originally appeared in the Nov/Dec issue of Procurement Pro.