The components selected during design shape financial outcomes long after schematic freeze. Initial procurement numbers rarely capture the product’s real price. Technical decisions made early introduce hidden expenses. When lower-grade parts enter production, defects surface, warranty claims increase and reputational damage follows. The savings may show up now, yet remediation later often carries a far higher price. Here’s what those low-cost elements actually cost.

The real cost beyond the bill of materials

A cheap component can get expensive fast. For instance, a 25% tariff on specific chips can increase a $1 part to $1.25. This change adds up to a massive expenditure across thousands of products and ruins profit plans. This is a real issue with charges on Chinese goods, affecting many common electronic components.

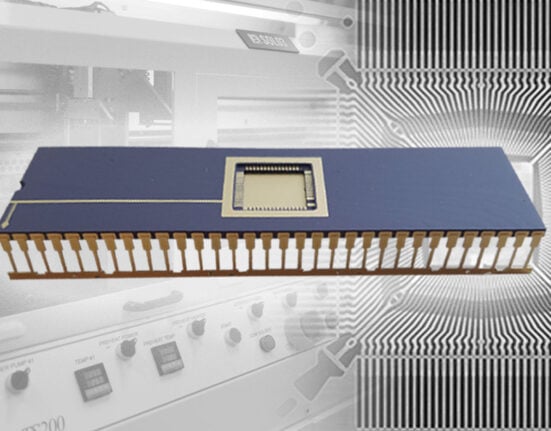

On top of tariffs, it now takes much longer to get certain parts. In 2025, the shortest lead times were at least two weeks for memory components like SSDs, while the longest were 42 weeks for DRAM and RLDRAM. This delay ties up the company’s money in unfinished products and slows down sales.

Manufacturing drag and quality leakage

Using cheap, low-quality components creates a trail of expensive problems that show up at every stage of the validation cycle. During early testing, these parts cause more product failures, leading to more rework and scrapped materials. United Nations data reports that global e-waste reached 62 million tonnes in 2022. These elements can turn otherwise functional materials into waste, adding to this figure.

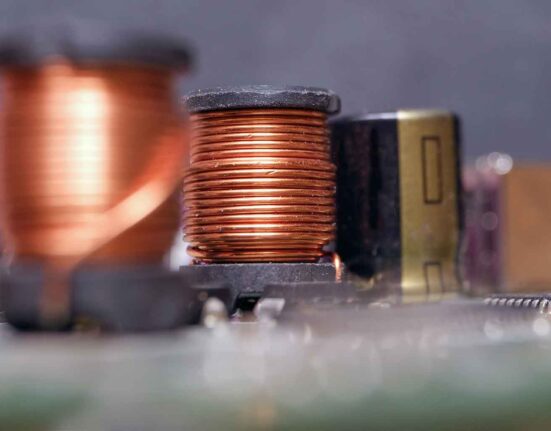

In manufacturing, low-quality parts can shut down the assembly line and force extra inspections, slowing everything down. These parts also cause random, hard-to-fix bugs, such as ghost resets or data corruption, that trace back to unstable memory or marginal voltage regulation. It wastes the time of senior engineers working on next-generation products.

Once the product reaches the customer, unreliable components drive higher return rates and support calls. Each failure costs the company money in shipping and repairs and damages its reputation.

Component obsolescence risks

Even if a unit performs well today, its life cycle may be limited. Parts reach end-of-life or face reduced availability as manufacturers discontinue production. This can force last-minute buys or design changes.

Obsolete components create unexpected costs in requalification, redesign or delayed production. Long lead times for alternatives further tie up capital and slow delivery. Planning for obsolescence during part selection reduces these downstream financial risks.

Reliability, safety, and regulatory exposure

In regulated industries like medical, automotive, and aerospace, the quality of a component is critical. These fields have strict safety rules, and using even one uncertified part can lead to lawsuits and massive recalls.

Automotive recalls illustrate the stakes. In just one week in 2024, Honda and Acura together recalled 750,000 vehicles due to an airbag defect. This was mainly due to the growing complexity of cars, which incorporate numerous electronic components that increase the risk of malfunctions.

Poorly made components can cause serious problems, such as overheating, short circuits or electrical interference that disrupts other systems. They can also corrupt software and data. In addition to the direct expense of recalls and legal fees, a company can also lose future contracts and fail safety audits.

Practical steps for financially sound selection

The choices an engineer makes early in the design process determine the product’s final cost. An innovative approach involves several key steps:

- Calculate the actual total cost of a part, not just its sticker price. This includes considering future expenses from warranty failures and shipping delays

- Implement a cash management system. It allows you to gain visibility into each purchase transaction and identify hidden or long-term costs that may accumulate

- Identify and approve backup suppliers early in the design process to avoid depending on a single source

- Review where a part comes from to understand risks from tariffs – as of 2025, countries such as Canada, Mexico, and China saw significant increases in taxes. In addition, ensure the component is not nearing the end of its life

- Work closely with supply chain teams and distributors to find good alternatives and stay aware of pricing trends

- Test components under real-world usage to analyse their actual performance, heat tolerance and stability

- Confirm that parts have the required certifications, especially when designing for regulated industries such as medical or aerospace

Partnering with a good parts distributor provides a major advantage. They can help with rigorous quality control and managing inventory to find cost savings without sacrificing reliability.

Minimise costs through smarter component selection

Every component choice is a financial decision, not just a technical one. When engineers look beyond the sticker price to consider the total cost, supply chain, and reliability, they protect the company’s profit, schedule, and reputation right from the start.

About the author:

Devin Partida is the Editor-in-Chief of ReHack.com, and a freelance writer. Though she is interested in all kinds of technology topics, she has steadily increased her knowledge of niches such as biztech, medtech, fintech, IoT, and cybersecurity.