Did you know that a single distributor such as RS can supply everything needed to build and run a data centre?

Data centres sit at the forefront of industry discussion as operators assess how to balance escalating AI-driven compute loads with practical constraints on power, cooling, and space. Organisations are looking at how rising bandwidth requirements, growing energy consumption, and tighter environmental regulations will shape site design and equipment choices.

RS supports data centre development by supplying the full spectrum of physical layer components required to build, scale, and maintain modern facilities. From high-bandwidth Ethernet cabling and LSZH-compliant wiring to modular power connectors, sensor-network interconnects, environmental protection hardware, and uninterruptible power solutions, it offers a consolidated source of equipment essential for uptime-critical operations. Its portfolio enables operators to simplify procurement, maintain compliance with global standards, and ensure that every subsystem – from data transmission to power distribution – performs consistently under demanding workloads.

When a data centre fails, the culprit is rarely the server itself. More often than not, it is the physical infrastructure that no one thinks about; cables that carry terabytes of data per second, connectors that must maintain signal integrity under constant thermal stress, or power distribution systems that can’t afford a single point of failure. With AI workloads driving data transfer speeds from 56Gbps today toward 224Gbps in the next few years, the physical layer is becoming a bottleneck that determines whether data centres can deliver on their promises.

Speed demands pushing physical limits

The trend of AI-optimised infrastructure has changed what data centre operators need from their cabling systems. While standard compute is satisfied with Cat6A Ethernet running at 10Gbps, today’s GPU clusters and machine learning platforms are now driving toward 224Gbps and beyond. For example, PCIe Gen 5 interfaces now operate at 32Gbps using NRZ encoding, which means the cables connecting these systems must maintain signal integrity across temperatures that can swing from ambient to +40°C or higher in high-density racks.

Lapp’s ETHERLINE Cat7 cables are a great solution for meeting data centres cabling needs. These cables feature S/FTP shielding and abrasion-resistant polyurethane jackets rated for industrial facilities, and can sustain up to 10Gbps data rates operating in temperatures from -40 to +90°C. For data centres pushing toward higher performance, the shielding of these cables improves electromagnetic compatibility and avoids crosstalk in cable bundles where hundreds of connections run in parallel through overhead trays or raised floors.

TE Connectivity’s Ethernet cables also offer data centres a stable option as bandwidth demands increase. They combine controlled impedance construction with robust shielding to minimise insertion loss and reduce susceptibility to electromagnetic noise in tightly packed racks. The cables design support consistent transmission at higher data rates, help maintain channel performance over longer runs, and resist thermal and mechanical stress common in facilities where equipment operates toward +40°C. This makes them suited for operators scaling GPU clusters or other high-speed architectures that place additional strain on physical interconnects.

High-speed data transmission in data centres also requires sturdy board-level interconnects. Amphenol Edge connectors cover high-density solutions with pitch options down to 0.6mm, supporting configurations of up to 74 contacts for compact server architectures.

Fire safety as a design imperative

Perhaps no aspect of data centre infrastructure generates more regulatory scrutiny than fire safety. When cables burn, they release hydrogen chloride and other corrosive gases that can destroy sensitive electronics even in areas far from the fire itself. This is why low smoke zero halogen (LSZH) cables have become a de-facto standard in European data centres and are increasingly required globally.

HellermannTyton LSZH Ethernet cables help to meet IEC 60332 and IEC 60754 standards, ensuring that if combustion occurs, smoke production remains minimal, and no halogenated acids are released. Lapp’s halogen-free high-temperature cables are rated up to 125°C and can provide additional sourcing flexibility for compliance with critical fire safety standards.

Power distribution requires industrial-grade reliability

While data cables get most of the attention, power distribution is where data centre reliability truly lives or dies. The cost of data centre downtime is estimated at $9,000 per minute, which means every connector in the power path must deliver absolute reliability under continuous load. This is where industrial connector systems like HARTING’s Han modular series prove their value.

Han connectors can handle current loads up to 1,400 amps while maintaining IP65 to IP69K ingress protection. In practice, this means maintenance teams can perform hot-swaps and reconfigurations without shutting down entire power distribution units. This quick-disconnect mechanism allows technicians to change modules in seconds rather than minutes, reducing mean time to repair and minimising exposure to live circuits. For data centres operating at availability targets of 99.999% uptime, seemingly small efficiency gains can translate directly to meeting their service level agreements (SLAs).

Protecting data centre power systems also requires uninterruptible power supplies to bridge the gap in the event of utility failure before backup generation comes online. APC’s UPS are available in line-interactive topologies with hot-swappable batteries for maintenance without downtime and SmartConnect monitoring for integration with facility management systems.

Environmental monitoring adds layers of complexity

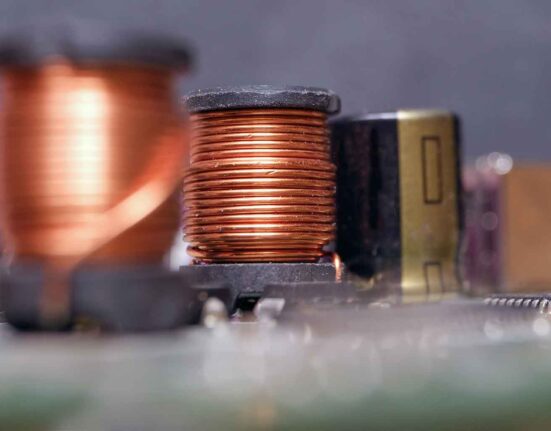

While moving data and power, data centres must also monitor environmental conditions to avoid thermal runaway, detect water leaks, and track airflow efficiency. This creates demand for sensor networks that are themselves built on specialised cabling infrastructure. Molex’s M12 connector systems, rated for 4A at 250V with IP67 protection, enable these sensor networks to operate reliably in humid, temperature-variable conditions near cooling systems and under raised floors.

Another crucial aspect of data centre design is ensuring that connections remain stable over several years of operation despite heavy vibration from HVAC systems, thermal cycling from variable loads, and occasional water exposure from condensation or minor leaks. Cable glands from manufacturers like Lapp’s Skintop series provide strain relief and environmental sealing, preventing slow degradation that can turn a reliable monitoring system into a source of false alarms and maintenance headaches.

Conclusion

The global data centre market growing rapidly implies that infrastructure decisions are being made in thousands of facilities worldwide, from hyperscale complexes to Edge computing nodes. For data centre operators, building infrastructure that is able to handle AI workloads and meeting strict uptime requirements involves component sourcing from reliable vendors.

RS maintains inventory across a broad range of categories, including Ethernet cables, LSZH-compliant wiring, modular power connectors, IP-rated components, and environmental protection hardware. Its role extends beyond stocking components; it supports engineers with clear technical documentation, compatibility guidance, and access to recognised manufacturers. This combination helps operators simplify procurement, reduce integration risks, and maintain long-term reliability across complex infrastructures.

Its breadth of supply means organisations can build and upgrade facilities with confidence that replacement parts, complementary products, and compliance-ready options remain readily available.

For additional information on any of these products or to locate a distributor in your area, please visit the website.