When equipment is engineered to outlast the parts that comprise it, proactive obsolescence strategies are essential to ensure production and replacement parts remain available even as component manufacturers move on to next-generation technologies, something they’re doing at a faster rate than ever to remain competitive as customer preferences shift.

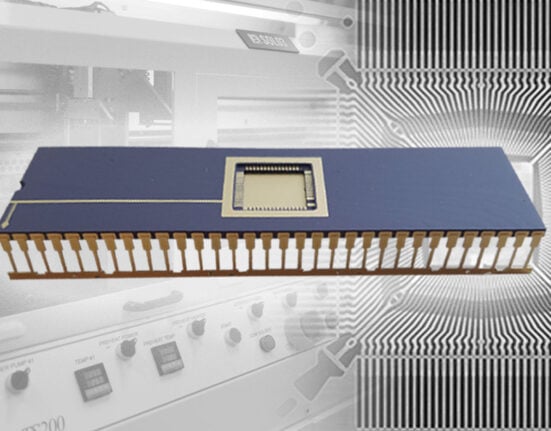

Original component manufacturers (OCMs) cease production on an estimated 470,000-plus components every year as they retool for new products with greater demand and higher profit profiles. High-end analog devices, microcontrollers, memory devices and FPGAs are continually displaced by newer iterations under the guise of portfolio management. The obliteration of Moore’s law with fast-evolving AI chips exacerbates the trend. Consequently, component lifecycles are measured in years (and not many, at that), with their functional life far exceeding their market viability. But equipment lifecycles in the mil/aero, medical, industrial, and other sectors are often measured in decades, creating a mismatch with particularly costly ramifications.

Engineers in high-stakes and tightly regulated sectors are loathe to embark on expensive, time-consuming redesign and recertification when a part is put on end-of-life (EOL) status. But those producing expensive, technically complex equipment are particularly vulnerable when components crucial to functionality are put on notice. Aware of the bind this puts their customers in, OCMs strive to give them a 12- to 24-month window for last-time buys, but that window can shrink dramatically when competitive concerns, fab capacity, or geopolitical headwinds come into play.

As they say, the best offense is a good defence. The question is not whether a part will become obsolete, but when. The most effective EOL strategies bridge the gap between equipment and component lifecycles.

The growing importance of extended manufacturing

Extended manufacturing agreements give equipment manufacturers long-term, reliable access to critical components. At the behest of their customers, OCMs will collaborate with authorised partners to keep component production going, even if they’re no longer manufacturing the parts themselves. Customers may also reach out to authorised manufacturers on their own to secure an agreement. The benefits are mutual. OCMs stay in their customers’ good graces, making them much more likely to sustain the relationship over time. Equipment manufacturers are assured that the parts they’re using are licensed, warrantied, and identical in form, fit, and function to those originally produced by the OCM.

Ideally, OCMs will begin working with their authorised extended manufacturing partners well in advance of shutting down production lines. That one to two-year runway provides ample time to shift responsibility. Putting time and resources into understanding obsolescence horizons and creating extended manufacturing strategies to match allows OEMs and their customers alike to be much better prepared.

Extended manufacturing can also be of particular relevance when engineers are trying to get their hands on components originally introduced years ago. Documentation may be scarce. Those familiar with the design may be hard to track down. The tooling needed to remanufacture the parts is who-knows-where. It’s an arduous undertaking, but necessity has a way of opening doors. If wafers and dies are still available, extended manufacturing partners with deep roots and strong relationships are perhaps the only ones that can get it done.

Extended manufacturing isn’t a stopgap; it’s a continuity strategy

Obsolescence shows no signs of abating. Components will be discontinued long before the equipment they’re put into becomes outdated itself. Long-term, reliable access to authorised components through extended manufacturing is the antidote to rapid technological advancement, industry consolidation, and the adoption of advanced fabrication processes that threaten the availability of legacy components. Flip Electronics Manufacturing Services (FMS) provides innovative, reliable, and customer-focused solutions to bridge this lifecycle gap, ensuring a consistent supply of essential components.

About the author:

Adam Mold serves as the Director of Business Development for Flip Electronics Manufacturing Services, while also managing several of Flip’s key authorised suppliers. With over 25 years of global experience in the electronics components industry, Adam brings extensive expertise in both distribution and manufacturing. He spent more than two decades at Future Electronics in Europe and the Americas, leading Marketing Business Units and overseeing Focus Suppliers. For the past three years, he held the role of Senior Director of Global Distribution Marketing at Infineon Technologies within the IoT and Edge AI-focused Connected Secure Systems Division.