It is not only the number of discontinued electronic parts and components, which has been rising steadily for years, which is causing headaches for many manufacturers of durable industrial goods. Geopolitically induced raw material shortages and trade restrictions, brain drain, increasingly stringent environmental regulations, cyberattacks on important internal data and processes, natural disasters, etc. are also increasingly proving to be latent risk factors for long-term supply security.

In order to fully meet all these challenges, Axel Wagner, honorary chairman of the board of the non-profit industry association COGD (Component Obsolescence Group Deutschland) e.V., founded in 2005, predicts that sooner or later there will be no way around introducing strategic obsolescence management, at least in larger industrial companies.

“Many of our more than 170 member companies successfully embarked on this path years ago, but outside the COGD we still see a great need for action in this area. As a non-profit organisation, it is important to us to use our free public lecture series and discussion panels to show external companies cost-effective ways out of the obsolescence trap. Unfortunately, many manufacturers of industrial equipment and systems are still unaware of the growing importance of highly efficient, proactive obsolescence management for business success, even though up to 50% of the total costs incurred over the entire product life cycle of particularly durable equipment and systems can already be directly or indirectly linked to various types of obsolescence,” says Wagner.

Exhibitors and visitors to productronica 2025 can learn about some strategies and methods for reducing potential obsolescence risks on 21st November from 9:30am to 12pm at the COGD Obsolescence Forum organised by COGD in cooperation with Messe München at the ‘PCB & EMS Speakers Corner’ in Hall B3.

- btv technologies will demonstrate how logistics service providers can support electronics and EMS companies in terms of sustainable value creation, compliance, and future security with innovative concepts and certified processes (DIN EN IEC 62435). The focus will be on auditable long-term storage, digital traceability, best practices for maintaining functionality, and flexible aftermarket strategies. Participants will receive direct implementation ideas from the automotive sector

- As an electronics service centre specialising in industrial electronics, Eichler gets to the bottom of the question of how obsolescence can be controlled with an individual supply strategy and presents the three stages of obsolescence management specifically for maintenance personnel

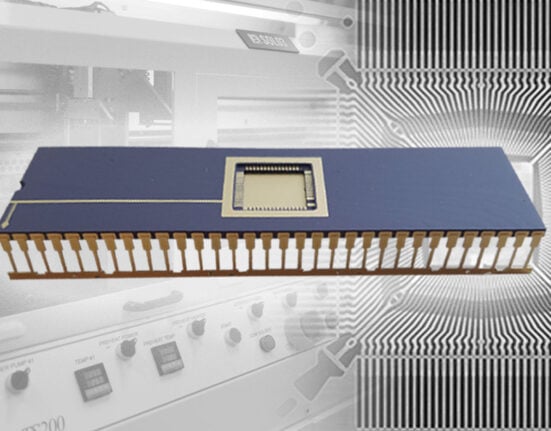

- FMD (Research Factory Microelectronics Germany), a collaboration between the Fraunhofer Microelectronics Group and the Leibniz Institutes FBH and IHP, will present the APECS pilot line, which is expected to make an important contribution to preventing obsolescence in the future. APECS (Advanced Packaging and Integration for Electronic Components and Systems) offers the opportunity to reproduce electronic components and systems threatened by obsolescence through strategic alliances between users, manufacturers, and European research and technology organisations. By reducing dependence on foreign suppliers and strengthening European capabilities in critical technology areas, the pilot line plays a crucial role in strengthening Europe’s technological resilience

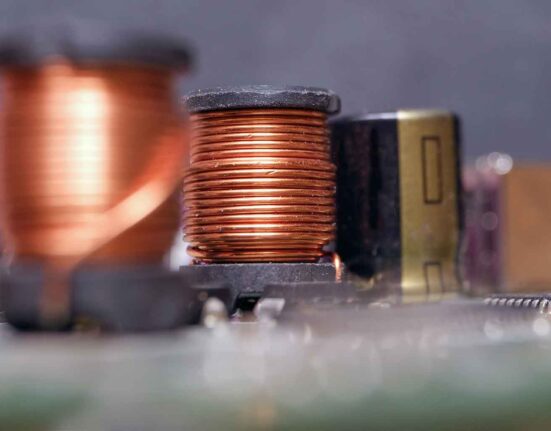

- In its presentation, HTV Alter Technology will discuss how long-term preservation strategies can help prevent obsolescence. The aim of these strategies is to extend the usability of electronic parts beyond their typical life cycle. The advantages and disadvantages of storing components versus entire assemblies will be discussed, aging processes will be highlighted, and storage methods will be compared

- Sourceability clearly explains to presentation attendees why the obsolescence of components or systems is not the only problem for a manufacturing company. Another risk that is unfortunately still often underestimated is the sudden loss of expertise due to the departure of experienced, long-term employees

The various solutions presented in the presentations illustrate that there are now a wide range of options and measures available to protect against the negative consequences of obsolescence. What is still lacking in some cases is the willingness to use them consistently and, above all, proactively. Wagner: “Unfortunately, there are still far too many manufacturing companies that do not take the cost risks associated with obsolescence into account in their project planning, or do so only to an insufficient extent. In practice, this can prove to be a fatal mistake, because sometimes a single missing component in production or maintenance, worth just a few cents, is enough to trigger immense follow-up costs. But with our events, we at COGD want to help ensure that this does not happen in the future.”

More detailed information on the COGD Obsolescence Forum taking place on 21st November at productronica 2025 and the other activities of the Component Obsolescence Group Germany can be found on the COGD website at www.cog-d.de