It’s a tale as old as boxes. You order a part. The part arrives in a box big enough to house a small family, and your order sits, lonely, rattling around somewhere in its depths. It is, quite literally, a waste of space.

Could a proof of concept using NVIDIA’s Jetson Nano Orin compute execute an AI algorithm that helps companies save time and space when packaging goods for boxes? With regulation looming and heavy fines incoming, this might just be the thing you are looking for.

Limited time leads to waste

Excessive waste is a problem for companies and for the planet, and part of the creation of that problem is time pressure, says Creative Technologist Jude Pullen. Humans who work in factories packaging goods to ship around the world tend to use bigger boxes than they need, erring on the side of caution to avoid repacking. Repackaging would take time, which they don’t have – but it also leads to systematic overboxing.

Existing operational procedures struggle to juggle huge product catalogues with the multitude of items available, packaging them into a limited number of box sizes whilst under time pressure.

The order comes in. It gets packed. It ships out – quickly. Such is the design of our immediate culture.

Business Waste reports that during Black Friday alone, oversized packaging results in 300,000m3 of empty box space being transported across the country. This equates to 3,000 tonnes of unnecessary cardboard used in a single day. As a consequence, almost 25,000 extra van journeys are added to the UK roads, producing 600 tonnes of CO2e.

The ideation phase

As a freelance creative technologist and prototyping expert, Pullen approaches projects with curiosity, creativity, and compassion. He spots gaps in the market and figures out what’s not working and why. So, naturally, it was a practically empty box and the classic game of Tetris that led him, with the backing of RS DesignSpark, to look deeper into the consequences of waste and what can be done about it.

Already active in the Fight to Repair, Pullen is no stranger to the cost of e-waste – having seen it first-hand. But what about the consequences of wasted space? Well, this is an area he has been thinking about for a while, since 2020 in fact.

“I had a vision of an AI ‘boxing match’ … There would be a heat to decide which team could create the best algorithm,” he said.

However, that concept was expensive, then COVID-19 hit and “all bets were off.” Once life resumed, the project got shelved. Yet the idea never left him.

“I’ve been chipping away at sustainable design since,” he said. And what he found during this time was that it is “very hard to find clients who want to spend money on sustainable issues if there’s not a financial imperative.” Here, he gives credit to RS DesignSparks, who “took the project on ethics and doing the right thing.”

And it turns out that doing the right thing is the right thing to do – and could tangibly affect the bottom line.

Pullen met the head of packaging for RS, Liam Dowds, who explained that this is more business-critical than initially thought. ‘Packaging and Packaging Waste Regulation‘ (PPWR) is coming this year, and it will be very significant to many logistics operations for ‘big box movers’. As Pullen notes, it is about to give companies “a rude awakening.”

What is PPWR?

PPWR is a regulatory framework that strengthens and incorporates Extended Producer Responsibility (ERP) schemes, making producers financially and physically responsible for the entire lifecycle of their packaging. Both of these fall under Environmental, Social, and Governance (ESG) regulation.

The new PPWR regulation effectively means that companies found to have more than 50% of wasted space will be fined. This includes boxes using excessive padding and paper. This is a phased implementation starting this year through to 2030. Some EU countries are even looking at 40% being the limit.

The consequence of wasted space

When talking about the consequences of wasted space, Pullen notes that there are three areas of concern:

- Environmental: more cardboard, fillers, transport volume, CO2, water, and energy are used

- Financial: higher shipping and material costs are incurred. Potential risk of damage to products from being shaken around or breaking through the packaging, aka, “burst out”

- Customer experience: poor unboxing experience, goods potentially arriving damaged, perceived wasteful company

“Waste has this duality to it. If you reduce waste, it’s good for the planet … I can’t guarantee that sustainability is going to raise revenue, but I can guarantee that it will reduce losses … improving your bottom line.”

What is the POC?

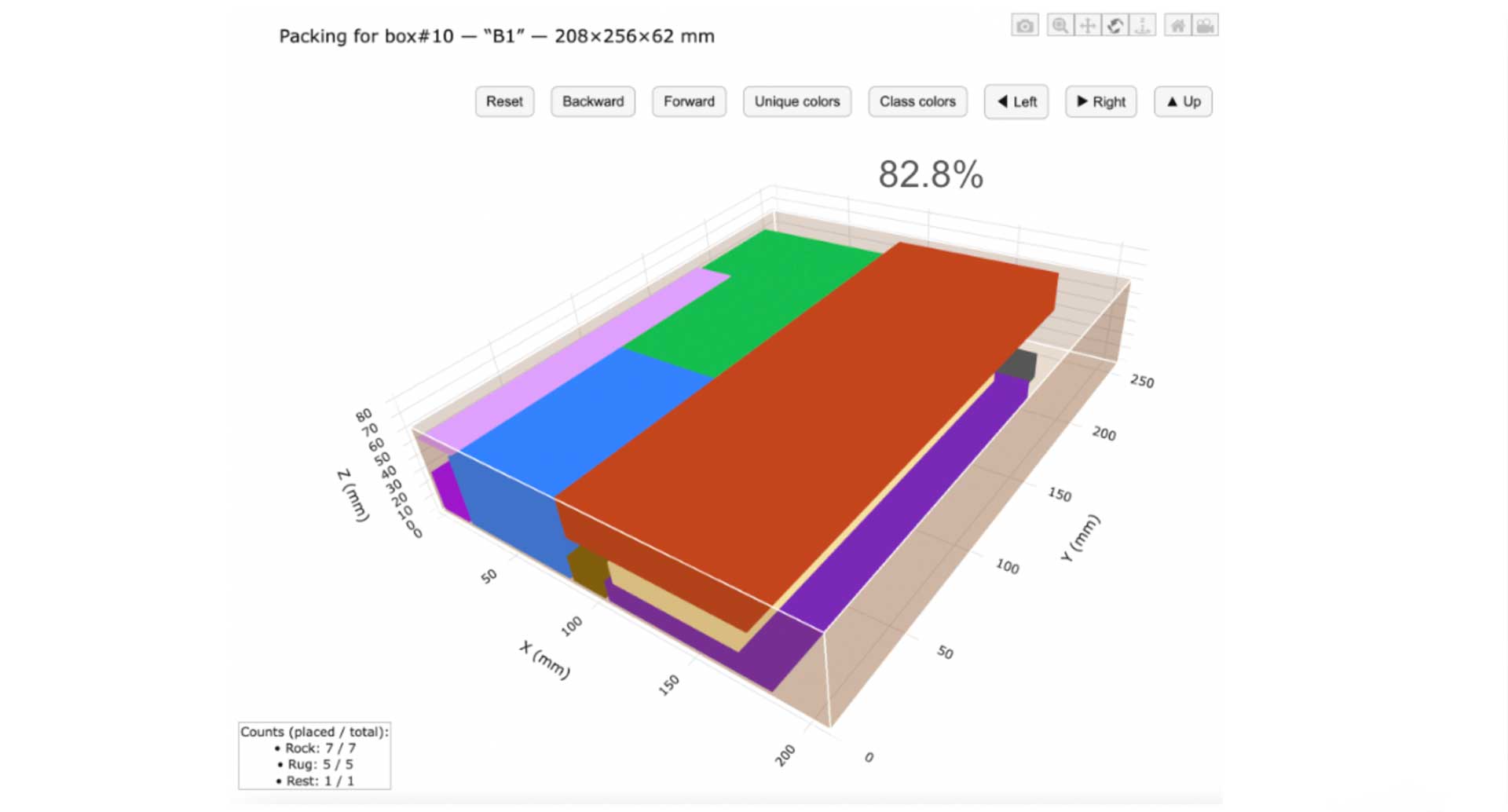

The algorithm that both Pullen and Brian Schwab, Interaction Designer, have created does more with less. As his title suggests, Pullen used creativity (Tetris) with technology (AI) to create a proof-of-concept algorithm that could reduce company losses, giving the bottom line a health kick, helping towards ESG goals, and ultimately saving companies from hefty fines down the road.

The algorithm triages orders, Pullen tells me. It won’t tell you to pack tiny resistors with a big pole. Or to put heavy items with fragile ones. It tells you what you can put into a box to maximise your use of space. Once it correctly segments orders, it then gets down to the dimensions, “that’s when it plays Tetris, and that’s where the AI compute comes in – and we haven’t wasted all of that compute energy, CO2, water, electricity.”

Pullen helped to triage all of the data “in an intelligent, humanistic rationalisation”, and Schwab has written “sleek, elegant code” that complements the ethos of intelligent rationalisation. This, Pullen tells me, is what they refer to as the “Pareto rule intelligence.”

“We’ve tried to strip it back to work hard on the 20% that actually needs non-polynomial style computation,” he said.

Being a staunch advocate for a human-centred approach to technology, Pullen explains that this algorithm is a solution to a challenge that centres on the step in the process that humans couldn’t easily do.

“We take the heavy lifting out of the time pressure people are under to find the right box, the right fit, and the right packing method quickly.”

The concept runs on NVIDIA’s Jetson Nano Orin, which not only has the benefit of not having to share data with the Cloud, therefore preserving privacy, but it is also a powerful, low-cost tool compared to having to use machine learning cameras and LiDAR, etc. It works so well that Pullen believes it could run whole company datasets and still not use all of its capabilities.

Proving the concept with open-source code

This proof-of-concept is only the first phase, and its code is open. This, Pullen says, will be especially beneficial to startups and SMEs.

“Large enterprises likely already have something like this in place. They might want to borrow bits here and there, but phase one would be really helpful to startups right the way through to SMEs.”

By putting this AI assistant in place, it gives operations teams a decision-supporting tool that:

- Removes guesswork and reduces overboxing

- Delivers a reduction in wasted space, which, at volume, could be significant for the bottom line

- Frees humans from some of the “difficult and dull” parts of the job – the constant box-picking – so they can focus on:

- Judgement

- Exceptions

- Higher-value work

However, phase two is a step that Pullen is keeping firmly under wraps, and this phase will target Enterprise.

“The next phase of the project is where we understandably make it proprietary,” he says. “Other companies have the opportunity to make it suit their needs.”

Conclusion

By addressing the persistent issue of wasted space in packaging, it becomes clear that sustainability is not an abstract ambition but an operational decision. Over-boxing, driven by time pressure, complex catalogues, and human guesswork, carries measurable environmental, financial, and customer experience costs. Reducing this inefficiency does not require removing people from the process; it requires better tools that support faster, more informed decisions at the point where they matter most.

The AI algorithm developed by Pullen and Schwab demonstrates how this can be achieved in practice. By acting as a decision-support system rather than an automated replacement, it removes much of the routine guesswork from box selection while keeping human judgment firmly in control. Even modest improvements can translate into meaningful savings at scale. Not to mention lower emissions, fewer damaged goods, and a smoother customer experience. At the same time, it helps companies prepare for incoming PPWR requirements, where documented reductions in packaging waste will no longer be optional.

Ultimately, it shows how sustainability, efficiency, and commercial reality can align. Using AI as an assistive tool allows operations teams to work more effectively, frees people from repetitive tasks, and delivers tangible benefits to businesses, particularly SMEs and startups operating under tight margins. In this context, the work by Pullen and Schwab is less about technology for its own sake and more about creating tools that are practical, human-centred, and capable of benefiting companies, customers, and the planet at the same time.

If you are interested in knowing more about the project, contact Jude via www.judepullen.com and check out the blog series on RS DesignSpark