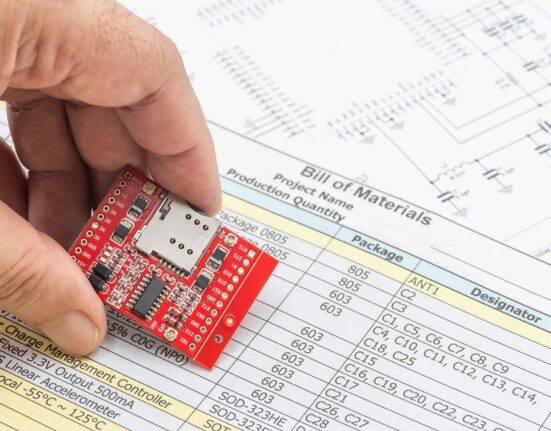

Date code restrictions have long been a concern for both distributors and manufacturers of electronic components.

Many customers are hesitant to accept components with date codes older than three years, even when these parts remain perfectly functional. This ingrained mindset often leads to unnecessary supply chain challenges, wasted resources, and avoidable electronic waste (e-waste).

As sustainability becomes a driving force in the electronics industry, it’s time to reevaluate the relevance of date codes and consider how rethinking these policies can enhance environmental, social, and governance (ESG) initiatives.

The origins of date code practices

Date codes were initially introduced as essential tools for traceability and quality control. They provided manufacturers with a quick method to identify production batches, address potential defects, and manage recalls effectively. In industries where safety and reliability are paramount – such as aerospace, automotive, and medical devices – date codes helped ensure that faulty components could be swiftly traced and removed from circulation.

However, the landscape of electronics manufacturing and distribution has evolved significantly. The original purpose of date codes as ‘sell-by’ indicators no longer aligns with the realities of modern supply chain practices. Conservative estimates based on worst-case storage conditions have been the norm, but today’s distributors and procurement professionals employ advanced storage technologies to mitigate risks. Temperature and humidity are meticulously controlled, corrosion and mould are prevented through proper packaging, and sensitive devices are safeguarded against electrostatic discharge. These measures allow components to outlast traditional shelf-life estimates by a considerable margin.

Moreover, the diverse applications of electronic components challenge the one-size-fits-all approach to date code relevance. While consumer gadgets may have a limited lifespan, industrial machinery, medical equipment, and military devices often operate for decades. This disparity underscores the need for more nuanced, evidence-based policies regarding component viability.

Reevaluating date code relevance: what the data says

Recent studies have provided compelling evidence that date code restrictions are often unnecessarily rigid. For example, Rochester Electronics conducted extensive testing on components stored for up to 17 years. The tests evaluated solderability, package integrity, joint quality, electrical performance, and overall functionality. The results were clear: when stored correctly, these components remained electrically viable, with no degradation in mechanical or electrical properties.

Similarly, Texas Instruments (TI) has conducted long-term storage analyses, revealing that semiconductor products can maintain their performance for over 15 years, and in some cases up to 21 years, without exhibiting failure mechanisms. These findings challenge the outdated belief that components lose their reliability simply due to the passage of time.

Industry shifts: the ECIA’S updated guidance

Recognising the growing body of evidence, the Electronic Components Industry Association (ECIA) revised its Date Code Restrictions Guidance Document in June 2023. The updated guidance advocates for the elimination of general date code restrictions from purchase order requirements. Key recommendations include:

- Eliminating blanket date code restrictions in purchase orders

- Ensuring that components are sourced from manufacturers and authorised distributors who:

- Comply with packaging, shelf life, and storage requirements

- Support product warranties

- Distribute and adhere to product change notices, recalls, and quality alerts

- Implement robust order management processes to review and align with customer-specific date code requirements when necessary

The ECIA emphasised that general date code restrictions disrupt supply chain efficiency, delay order processing, and contribute to inventory aging. By shifting away from these outdated practices, the industry can enhance both operational agility and sustainability.

Clarifying industry terminology: date codes, shelf life, and warranties

One of the barriers to reforming date code practices is the confusion surrounding key terms. Date codes, shelf life, and warranties are often used interchangeably, leading to misunderstandings about component viability.

- Date code: an alphanumeric identifier indicating when a component was manufactured or packaged

- Shelf life: the period during which a component remains electrically viable under proper storage conditions. This is typically a conservative estimate

- Warranty period: the timeframe during which a customer can claim a replacement or repair if a component fails, as defined by the manufacturer.

Standardising these definitions across the industry can help stakeholders make informed decisions about component use, reducing unnecessary waste, and promoting sustainable practices.

Unlocking the value of unsold inventory

Rethinking date code restrictions offers significant sustainability benefits. Components that were previously considered obsolete due to arbitrary date code cutoffs can now be reintroduced to the market, reducing the volume of functional parts that end up in landfills. This shift helps mitigate the growing problem of e-waste, which poses environmental and health risks worldwide.

In addition to environmental benefits, there are financial incentives. Manufacturers and distributors can recover value from excess inventory through resale programmes. These programmes allow new, unused components to be sold on the secondary market, often through partnerships where profits are shared between original distributors and resale platforms. This not only reduces waste but also enhances supply chain resilience by expanding the pool of available components.

Building a sustainable future for electronics

The transition away from rigid date code restrictions marks a pivotal moment for the electronics industry. By adopting more flexible, evidence-based policies, manufacturers and distributors can improve supply chain efficiency, reduce waste, and support ESG goals. Embracing real-time inventory management, advanced tracking technologies, and collaborative supply chain practices will be key to maintaining product quality without relying on outdated date code constraints.

Ultimately, this paradigm shift aligns with the industry’s broader sustainability objectives. It encourages responsible resource management, minimises environmental impact, and fosters a circular economy where electronic components are valued for their functionality, not just their manufacturing date. By rethinking date code practices, the electronics industry can lead the way toward a more sustainable, efficient, and adaptive future.

This article originally appeared in the March/April issue of Procurement Pro.