By Fusion

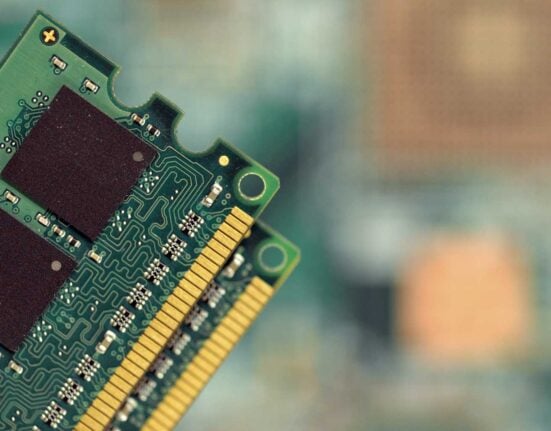

When engineers talk about quality assurance in electronic components, the conversation often centres around semiconductors – ICs, processors, and memory. But the real sleeper threat in the supply chain lies in the less glamorous workhorses: passive components.

Capacitors, resistors, inductors, and other passives make up the backbone of every circuit, and yet their degradation over time or mishandling during storage can quietly undermine product reliability.

The myth of passive stability

There’s a common misconception that passives are more stable or immune to failure modes compared to active components. While they might lack the complexity of ICs, passives are far from indestructible. In fact, their simple design can mask critical vulnerabilities:

- Oxidation: metal terminations on capacitors and resistors are highly susceptible to oxidation when stored in uncontrolled environments

- Moisture ingress: many passives are porous and can absorb moisture over time, especially in humid or non-climate-controlled warehouses

- Shelf-life decay: dielectric materials degrade over time, and many manufacturers assign strict shelf-life limitations based on packaging and storage conditions

These aren’t rare edge cases – they’re well-documented risks that affect component performance, solderability, and long-term reliability. Understanding these nuances is especially important for quality engineers responsible for long lifecycle applications or products operating in harsh environments.

The role of storage and environmental control

Humidity, temperature, and exposure to oxygen are the three main enemies of passive component longevity. In an ideal environment, components are stored in dry cabinets or sealed in moisture barrier bags (MBBs) with desiccants and humidity indicators.

However, in the open market, it’s not uncommon for parts to be stored in:

- Ambient temperature stockrooms without humidity control

- Original packaging that has been compromised or opened

- Reels that have been repackaged or relabelled multiple times

Even brief exposure to excessive humidity can initiate oxidation or micro-corrosion on terminations, which may not be visible to the naked eye but will impact performance during reflow or in-field use. For components intended for high reliability industries, this is a non-negotiable risk.

Best practices call for tight control of temperature and relative humidity (typically <5% RH), with inventory rotation and tracking protocols in place to ensure shelf-life compliance. Manufacturers assign Moisture Sensitivity Levels (MSLs) to guide proper handling – if those labels are missing or outdated, that’s an immediate red flag.

Electrostatic discharge (ESD) is another critical factor, especially when handling components in dry or low humidity environments. Choosing a distributor that adheres to ANSI/ESD S20.20 standards is vital. Fusion Worldwide is certified to ANSI/ESD S20.20, helping to protect sensitive devices throughout the supply chain.

Indicators of risk: what quality engineers should look for

When evaluating passive components from the open market, engineers should assess more than just appearance. Here are some red flags to watch for:

- Discolouration or corrosion on terminations

- Absence of MSL (moisture sensitivity level) labelling or manufacturer date codes

- Packaging that appears resealed or tampered with

- Reels with mixed lot codes or manufacturer inconsistencies

In addition to a visual inspection, engineers should consider implementing solderability testing, X-ray inspection for packaging uniformity, and cross-reference checks against OEM datasheets to ensure correct part number formatting and labelling. Older passives in particular – those stored near or past their date code threshold – require extra scrutiny before placement on a board.

Additionally, component provenance should not be overlooked. Requesting traceability documentation and chain of custody records from your distributor can help identify how the part has been stored, shipped, and handled throughout its lifecycle. The more visibility you have into the history of a component, the better you can assess whether it’s suitable for your application.

What to look for in a distributor around storage and handling

Quality begins long before testing. Distributors that take environmental control seriously should be able to provide detailed information on their storage conditions, including whether they use humidity- and temperature controlled zones and how they manage repackaging. These practices directly impact component longevity and performance.

This article originally appeared in the May/June issue of Procurement Pro.