By Frank Cavallaro, CEO, A2 Global Electronics

The electronics industry faces mounting challenges as governments enact stringent tariff regulations to protect domestic industries and address geopolitical concerns.

For procurement professionals in electronics, these new tariffs have reshaped sourcing strategies and emphasised the critical need for robust traceability systems.

The growing importance of traceability in electronics

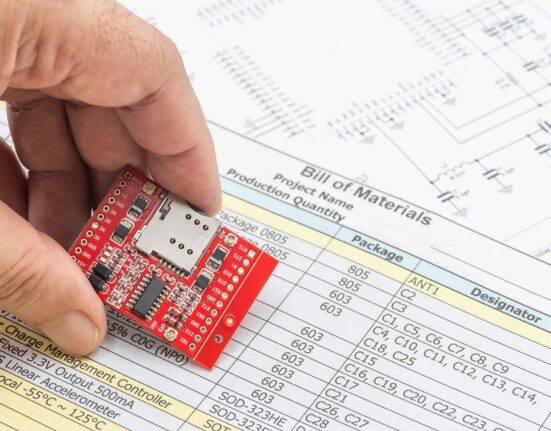

Traceability, the ability to track and document the origin, journey, and transformation of goods, has always been a best practice for global supply chains. However, new tariff regulations have elevated it to a regulatory requirement, particularly for electronics buyers navigating complex global networks.

The electronics supply chain is among the most intricate globally, with components frequently crossing multiple borders as they progress through the distribution network. This complexity makes it challenging to accurately document origins without dedicated tools or processes. Procurement professionals must now implement sophisticated systems that provide a complete, auditable record of each component’s path, ensuring they can meet growing compliance demands while maintaining efficiency.

Additionally, they must collaborate closely with suppliers to maintain accurate data, ensuring compliance and minimising disruptions caused by shifting regulations.

Key risks and challenges

Tariffs, particularly those targeting high-demand regions like China, have created several pain points for procurement professionals in the electronics sector:

- Rising costs: with duties adding as much as 25% to component costs, procurement teams must carefully evaluate sourcing decisions to manage budgets effectively

- Compliance complexity: navigating regulations requires precise documentation of country-oforigin information and adherence to classification codes, which burdens compliance teams

- Supplier disruptions: some suppliers may struggle to meet the documentation standards required under these new regulations, increasing the risk of sourcing delays or disruptions

Without the right tools and strategies, companies are exposed to penalties, customs delays, and reputational risks that could undermine their operations.

Proactive strategies to navigate tariffs

To mitigate these risks, forward thinking procurement teams are turning to advanced traceability systems and adopting proactive strategies to ensure compliance and control costs. Below outlines four key approaches:

Leverage advanced traceability tools

Cutting-edge traceability technologies, such as Blockchain and ERP systems, are enabling procurement teams to monitor country-of-origin data in real-time. These tools provide an immutable record of a component’s journey through the supply chain, ensuring compliance requirements are met.

Furthermore, these systems can automate the generation of audit reports, streamlining the compliance process.

Conduct supplier audits

Regular supplier audits are critical to verifying compliance with tariff regulations. These audits ensure suppliers adhere to required documentation practices and provide procurement teams with visibility into potential risks. Building relationships with suppliers who prioritise transparency and compliance is vital for long-term success.

Utilise tariff classification data

Analysing tariff classification codes and understanding their financial implications can help buyers make informed sourcing decisions. This process allows procurement teams to explore cost-saving opportunities, such as shifting production to alternative regions or renegotiating supplier contracts to account for tariff changes.

Maintain comprehensive documentation

Thorough record-keeping is fundamental for tariff compliance. Procurement teams should maintain certificates of origin, customs records, and detailed transaction histories to support regulatory audits. This documentation not only ensures compliance but also provides a layer of protection against penalties and disputes.

The long-term benefits of traceability

Beyond tariff compliance, traceability delivers lasting value to the electronics industry. By fostering greater transparency, companies can build trust with customers and stakeholders, mitigate risks, and strengthen their overall supply chain resilience. Traceability also aligns with broader industry trends, such as sustainability initiatives and ethical sourcing, which are becoming increasingly important to customers and regulators alike.

A strong traceability programme also drives operational efficiency. By gaining detailed insights into the supply chain, companies can identify inefficiencies, reduce waste, and optimise workflows. This holistic approach not only ensures compliance but can also uncover significant cost savings, further demonstrating the value of traceability beyond regulatory requirements. For procurement teams, these efficiencies translate into reduced lead times, enhanced supplier relationships, and the ability to pivot quickly when faced with new sourcing challenges.

Looking ahead

As global tariff regulations continue to evolve, the need for robust traceability in the electronics sector will only grow. For procurement professionals, this shift represents both a challenge and an opportunity to redefine their approach to compliance, cost management, and supply chain optimisation. By investing in traceability technologies and adopting proactive strategies, companies can navigate the complexities of today’s tariff landscape while positioning themselves for success in an increasingly regulated world.

With traceability as a cornerstone of their procurement strategy, electronics buyers can adapt to changing regulations, safeguard their operations, and drive long-term value across their supply chains.

This article originally appeared in the March/April issue of Procurement Pro.