Elmar Kert, Founder of Sluicebox, has spent over 15 years working in climate tech and sustainability. As CPUs, GPUs, and AI began to stretch data centres to their operational limits, Kert became increasingly drawn to the infrastructure challenges these developments posed. This led him to join AWS, where he spent several years focusing on the electronic components and semiconductor-based parts that make up a rack, as well as other supporting infrastructure equipment.

His work centred on understanding the environmental footprint – specifically component carbon emissions – of the electronics supply chain. However, he quickly encountered a major roadblock: there was no data layer or dynamic models available to scale insights efficiently across the millions of components that go into data centres. Like many others in the industry, Kert turned to consultants. With 7 figures approved by Amazon, he brought in a consulting firm to baseline just a handful of products.

What followed were polished, high-level 60-page PDF reports for each product. Yet none of them offered the scalability or dynamic insight needed to address broader component categories. Frustrated by the lack of actionable and scalable solutions, Kert left Amazon and started Sluicebox.

The company’s mission: to provide the industry with a way to baseline highly complex manufacturing components both quickly and economically.

Kert describes Sluicebox’s approach as a “dynamic, real-time LCA (Life Cycle Assessment)” – a departure from traditional lifecycle assessments. In the electronics and semiconductor supply chains, LCAs typically rely on multiple data inputs to evaluate a product’s environmental impact. One method is to use financial or spend-based data, but as Kert explains, this can be misleading: “Prices might fluctuate, tariffs might change prices as well. And so, with that, emissions, potentially, on paper, could go up and down, while the reality of things might look quite different.”

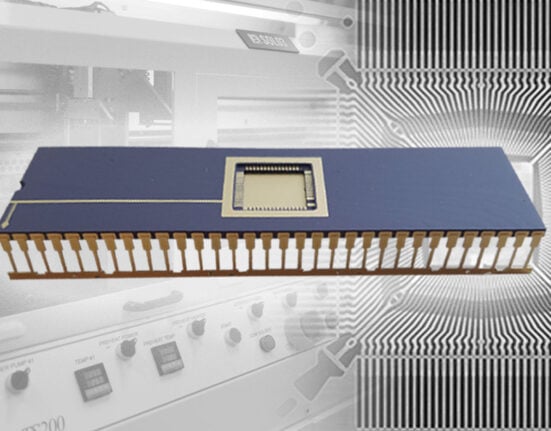

Instead of spend-based modelling, Sluicebox has created a product carbon engine focuses on process-based data streams. This is particularly relevant in semiconductor manufacturing, which involves multi-step, multi-location processes. Components often pass through various facilities, undergoing stages such as lithography, layering, and etching before reaching their final form. Kert notes that each of these steps contributes to the overall environmental footprint.

By analysing how products are physically made, rather than making estimates based on the price of the components, Sluicebox can identify specific emissions hotspots within supply chains and fabrication sites based on the actual manufacturing process

This real-time, process-driven methodology allows Sluicebox to deliver practical insights grounded in operational reality, rather than abstract spend-based assumptions. The result is a more accurate, actionable understanding of environmental impact at the component level.

Sluicebox adopts a dual approach to its modelling. The company initially developed an in-house hybrid AI model that draws on publicly available data and up-to-date scientific literature. This model integrates the most recent information to provide broad coverage for companies unsure of where to begin. By combining this public data with component specifications, Sluicebox enables customers to generate quick, initial insights.

Once customers engage with the initial outputs, they typically begin to infill more detailed data. Although companies rarely share specific data points directly, some have worked closely with Sluicebox to baseline every component they produce. This involves a granular analysis of the manufacturing processes: examining how many kilowatt-hours of electricity are consumed, how many cubic metres of gas are used, and the grams of material that go into producing each part.

In addition to public sources, the company has now begun working directly with suppliers to access higher-fidelity data. The aim is to offer what Kert calls “the highest level” of carbon emissions transparency for electronic components, helping the industry establish a more accurate environmental baseline.

Kert has observed a clear spike in demand for carbon emissions data and lifecycle analysis in Europe. He attributes this growth to two main drivers: regulatory pressure and customer expectations. On the regulatory side, recent EU legislation requires large companies to meet specific environmental reporting and sustainability obligations, prompting many to seek accurate, component-level data.

The second driver comes from major global customers. Many of these tech giants have set ambitious sustainability goals for 2030, 2040, and beyond, and they are now pushing those requirements down through their supply chains. As a result, suppliers are under growing pressure to align with these expectations.

Kert acknowledges that sustainability is a strategic priority for some companies, while for others, it remains lower on the list. However, it will ultimately become unavoidable. He notes that a significant portion of the industry will be compelled to act, either due to binding standards or pressure from influential players driving the direction of the supply chain.

This will result in a clear shift in how companies evaluate their suppliers, particularly in sectors like automotive. Kert explains that many firms now use scorecards to assess suppliers, incorporating a range of sustainability criteria. In some industries, Environmental Product Declarations (EPDs) have become mandatory just to be considered.

“If you can’t provide this data, we’re not doing business with you,” is the message some suppliers now receive.

This growing rigour extends beyond carbon emissions. Organisations are increasingly factoring in broader environmental and ESG concerns, such as PFAs (so-called ‘forever chemicals’), rare earth materials, and overall resource use. Kert highlights that sustainability is evolving into a more comprehensive framework for supplier assessment – one that spans environmental impact, social responsibility, and governance issues.

However, Kert highlights a growing tension: while parts of the supply chain demand comprehensive environmental data, many suppliers are unable to provide it due to gaps in access or capability.

This disconnect is exactly the niche Sluicebox aims to fill. The company provides a platform that enables suppliers to respond to these demands more effectively, even when primary data is not readily available. Through its methodology, Sluicebox uses publicly available information and process-based modelling to estimate environmental impact with a high level of accuracy.

Kert notes that once customers engage and begin supplying some data directly, the correlation between Sluicebox’s estimates and the primary data proves strong – with up to 90% accuracy. This level of precision is typically sufficient to satisfy regulatory requirements, further validating the company’s approach.

Sluicebox is currently in its scale-up phase, building on early success and growing interest across the electronics industry. The company is using its recent whitepaper as both a proof point and a strategic tool, highlighting collaborations with organisations such as Trustedparts.com, Western Digital, and Cliche.

“We’re going to be the exclusive vehicle to get these calculations out to the industry. This obviously expands our Trustedparts.com offering and fits well with the overall value proposition for Trustedparts.com from the start. It’s a new initiative, and we believe there is strong demand for it in Europe,” notes Victor Meijers, Senior Vice President, ECIA.

The current priority is ensuring access to its carbon emissions data across the industry. Kert explains that the ambition is to support a broad range of users – from those needing ‘quick insights’ to make initial progress, to advanced users integrating APIs and uploading detailed product data to scale assessments across their entire portfolio.

Click here to download a whitepaper with further information.